Els Series DC Electronic Load System

parameters

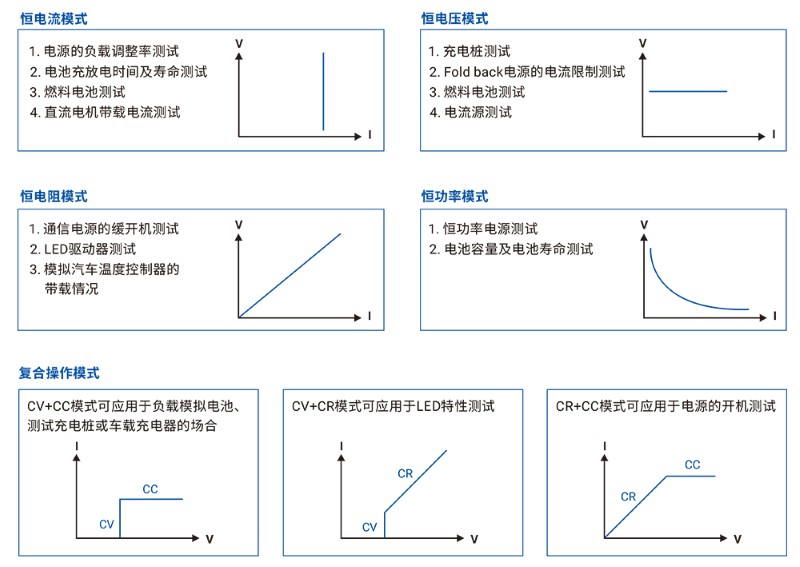

Supports 4 CV/CC/CR/CP basic modes, as well as CV CC/CV CR/CR CC composite working modes

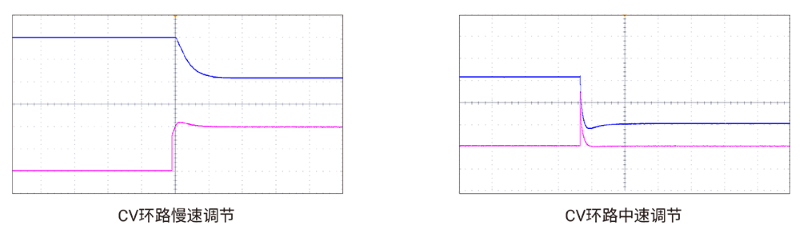

Current rise and fall slope can be set, CV loop feedback speed is adjustable

Ultra-high precision voltage and current measurement

Simulate load short circuit function

Automatic test function, complex test tasks a key to achieve

Support V-monitor/I-monitor monitoring function

Protection function is complete, with over voltage, over current, over power, over temperature alarm protection function, reverse alarm function

Panel with emergency stop switch

Equipped with rear door protection switch to improve operational safety

Standard USB data interface, support data load out

Uses standard SCPI communication protocol

The current standardized high-power DC electronic load cabinet consists of 7U electronic loads, and the current-carrying capacity of a single cabinet can reach 3000A and 67.5kW. Support multiple cabinet master-slave parallel expansion system power up to 294kW. The breaker switch at the bottom of the cabinet controls the on-off of the AC input. After power-on, one of the electronic loads will work in the master mode to synchronously monitor the status of all slave machines in the system. The standard emergency stop switch can cut off the AC power of all products in the cabinet to ensure safe operation.

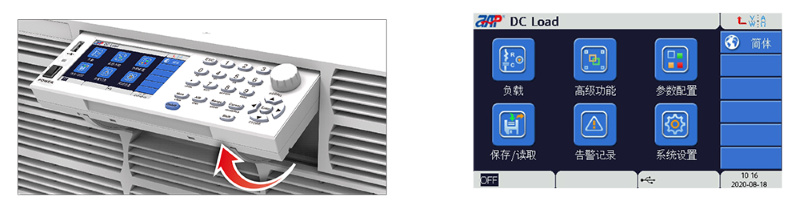

This series of programmable DC electronic loads (except some models) support the front panel flip function, and provide customers with simple and quick operation with large color touch screen, real-time update of input display and device status, and graphical display to make the display more intuitive.

Basic load mode

This series of programmable DC loads have CV/CC/CR/CP basic load constant mode, which can meet the test needs of a variety of occasions.

This series of programmable DC electronic loads can be set to five voltage response speeds: slow, slow, medium, fast and fast to match various characteristic power supplies. This performance can avoid the reduction of measurement accuracy or test failure caused by the mismatch between load and power response speed, improve test efficiency, and reduce the cost of equipment, time and expense.

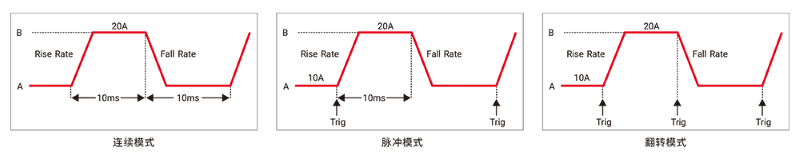

This series of programmable electronic loads can realize fast switching between different values under the same function, and supports dynamic current, dynamic voltage, dynamic resistance and dynamic power modes, of which dynamic current and dynamic resistance modes can reach 50kHz. This function can be used to test the dynamic characteristics of the power supply, battery protection characteristics, battery pulse charging, etc. The dynamic load test function is available in continuous, pulse and flip modes.

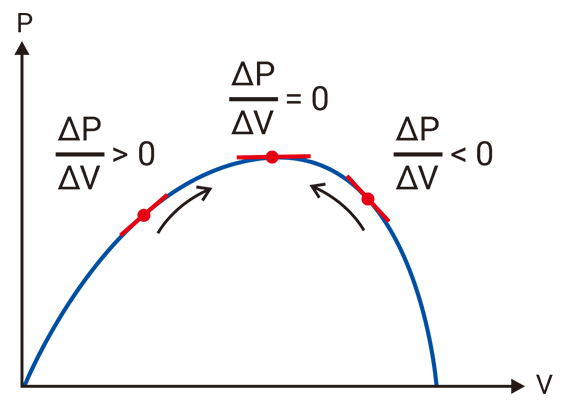

Mainly should be in the solar panel maximum power point tracking, through the maximum power tracking method, you can always dynamically find the maximum power point of the solar panel, to play the maximum effect of the solar panel.

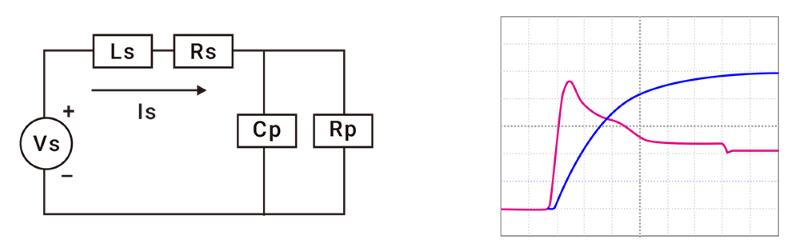

The simulation of capacitive load makes the pull-load current closer to the real situation. It is mainly used to simulate the startup and shutdown test of capacitive load. In order to avoid charging the capacitor on the main board at the moment of startup of the power supply, the surge current will cause the power supply to trigger overcurrent protection and thus fail to start up smoothly.

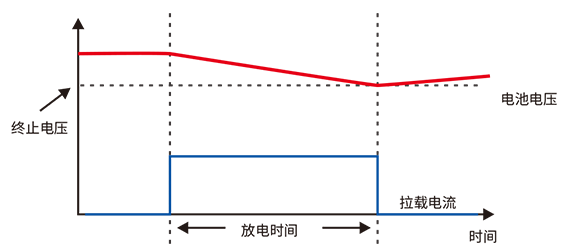

This series of electronic loads can discharge the battery in CC, CR or CP mode, and can accurately set and measure the cut-off voltage or discharge time to ensure that the battery will not be damaged due to excessive discharge. The discharge cut-off condition can be set according to the actual demand, and when the cut-off condition is met, the load stops pulling and the timing stops. During the test, parameters such as battery voltage, discharged time and discharge capacity can also be monitored in real time.