Mobile Energy Storage Test Equipment

parameters

Application areas: The

portable Energy Storage Products

including: FCT test system

ATE Test System

safety test system

aging test system

Product features:

- Strong compatibility, support AC-AC, AC-DC, DC-AC, DC-DC testing;

- Support various fast charging protocols;

- Support product communication: CAN, RS485;

- Modular system architecture for easy maintenance and quick replacement;

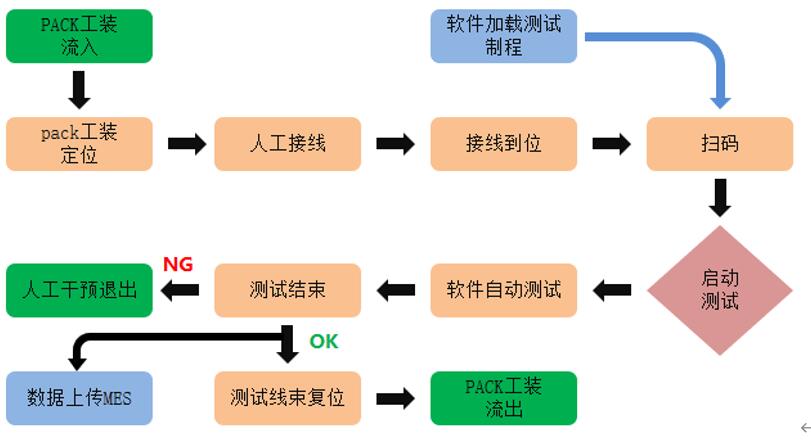

- Support scanning code to automatically retrieve test programs and upload test data to MES system;

- The unique instrument debugging and maintenance function is convenient for testing engineering personnel to maintain and adjust equipment, and can simulate manual testing;

- The open elastic architecture software platform can customize test projects according to the customer's new product requirements;

- Test results automatically produce various test reports and statistical analysis;

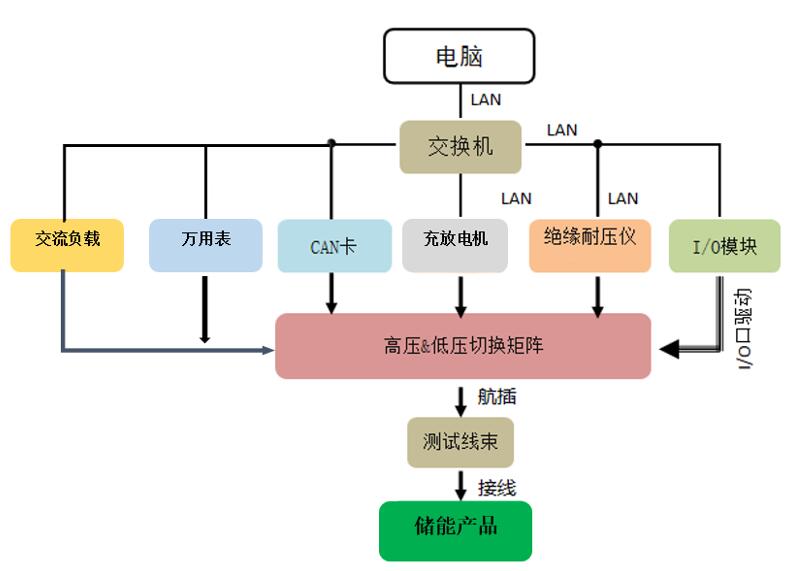

System Introduction

This equipment is used to realize the automatic test of insulation, total pressure, core pressure difference, DCIR, charging and discharging communication and other functions of energy storage system. The equipment mainly includes CAN card, charging and discharging motor, insulation withstand voltage meter, multimeter, relay switching system, supporting electric control system and upper computer software. The equipment automatically discriminates qualified and unqualified products according to the requirements of the test project, automatically records and saves the test data, and uploads it to the MES system. It can realize the matching of upstream and downstream production capacity of equipment to meet the needs of production process.

Application Industry

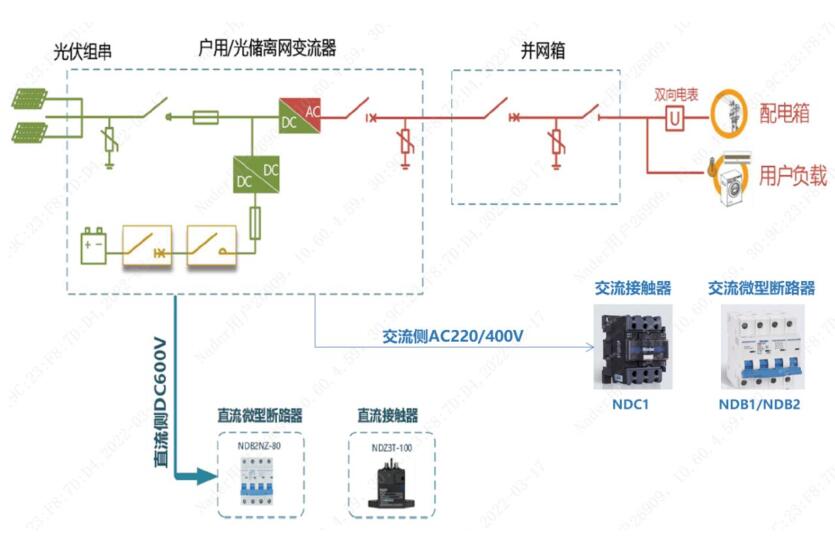

Used for industrial and commercial outdoor energy storage, home storage products three-in-one offline test equipment, functional modules: photovoltaic grid load;

Basic functions: solar panel charging test, inverter charging and discharging test, inverter communication test, EMS test.

Test Item

No. | Test Item | Test Method | Test Equipment | lower limit | Upper Limit | Unit |

1 | Insulation withstand voltage test | Measure the insulation resistance between the positive and negative electrodes and the shell (ground). 2000VDC, 5S | Safety gauge | 500 | infinity | MΩ |

2 | BMU Software/Hardware Version | Whether BMU software/hardware version is OK | CAN card | N/A | N/A | N/A |

3 | CSC Software/Hardware Version | Whether CSC software/hardware version is OK | CAN card | N/A | N/A | N/A |

4 | EMS Software/Hardware Version | Whether EMS software/hardware version is OK | CAN card | N/A | N/A | N/A |

5 | Serial Number Write/Read | EMS and product serial number | ||||

6 | Inverter Communication Protocol Test | 485 or CAN communication test | Communication Module | |||

7 | Relay Test | CAN or 485 communication control relay is closed or disconnected, and the corresponding output signal is tested. | Communication module multimeter | |||

8 | AC internal resistance | Measure AC internal resistance between total positive and total negative | Internal resistance meter | |||

9 | Total pressure test | Measure total pressure between total positive and total negative | Multimeter | 400 | 1500 | V |

10 | Maximum and minimum cell voltage difference | CAN message | CAN card | 0 | 25 | mV |

11 | Maximum and minimum cell temperature difference | CAN message | CAN card | 0 | 3 | ℃ |

12 | Current calibration | Calculation of K value and B value based on current value and measured current value of BMS | Charging and discharging motor | |||

13 | Current direction | Charge and discharge motor current direction is consistent with BMS direction | Charging and discharging motor | |||

14 | Current calibration | Calibrate the BMS current value against the actual current value | Charging and discharging motor | |||

15 | Quiescent current (when closed) | Test the quiescent current of the system | Multimeter | |||

16 | High pressure pre-charge test | |||||

17 | Photovoltaic charging test | Photovoltaic simulator access simulation photovoltaic charging | Photovoltaic Simulator | |||

18 | Charging DCIR | Charging internal resistance (60%-70% SOC 1C charge 10s) | Charging and discharging motor | 55 | 70 | mΩ |

19 | Discharge DCIR | Discharge internal resistance (60%-70% SOC 1C duscharge 10s) | Charging and discharging motor | 55 | 70 | mΩ |

20 | Charge and discharge test | The maximum current (300A) charging 3min, test the pressure difference, battery temperature rise, copper bar temperature rise, relay temperature rise; The maximum current (300A) is discharged for 3min, and the differential pressure, cell temperature rise, copper bar temperature rise and relay temperature rise are tested. | Charging and discharging motor CAN card | |||

21 | static pressure difference | Read the cell voltage of the message under static state, and calculate the differential pressure | CAN card | 0 | 10 | mV |

22 | Discharge differential pressure | <= 200mV | Charging and discharging motor CAN card | 0 | 200 | mV |

23 | AC on-load test | Maximum 100kw with load, test voltage and current | Power Grid Simulator | 0 | 100 | Kw |

24 | AC charging test | Connect to the mains to charge the product, test voltage, current, maximum 100kw | Power Grid Simulator | 0 | 100 | Kw |

25 | Cloud platform data upload | The corresponding data is uploaded to the cloud platform through Ethernet/WiFi, and the specific method is to be confirmed. | ||||

26 | Wireless Test | WIFI hotspot (2.4G5G), Bluetooth connection access, distribution network and configuration test; | WiFi Module Bluetooth Module | |||

27 | DIO Short Circuit Control Output Test | Provide at least 10 routes | DIO Module | |||

28 | DIN input test | The input level supports short-circuit signal and 12V/24V voltage signal (at least 10 channels are provided) | DIO Module | |||

29 | system power control | TBD | Power supply, load, CAN card | |||

30 | power quality test | TBD | power analyzer | |||

31 | Voltage/Frequency Response Test | TBD | Oscilloscope | |||

32 | Overload capacity test | TBD | Power supply, load | |||

33 | Protection function test | TBD | Fault simulation module, CAN card | |||

34 | Low Voltage Ride Through Capability Test | TBD | TBD | |||

35 | DBC file import parsing | TBD | TBD |